Conveyor systems

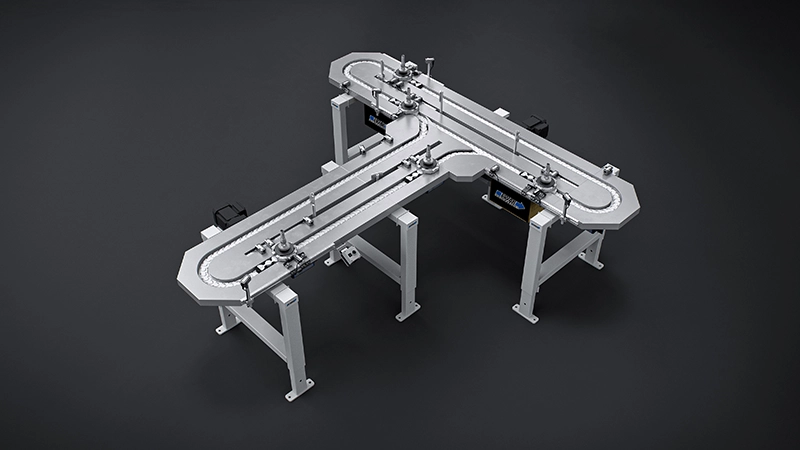

Pallet Conveyor Systems

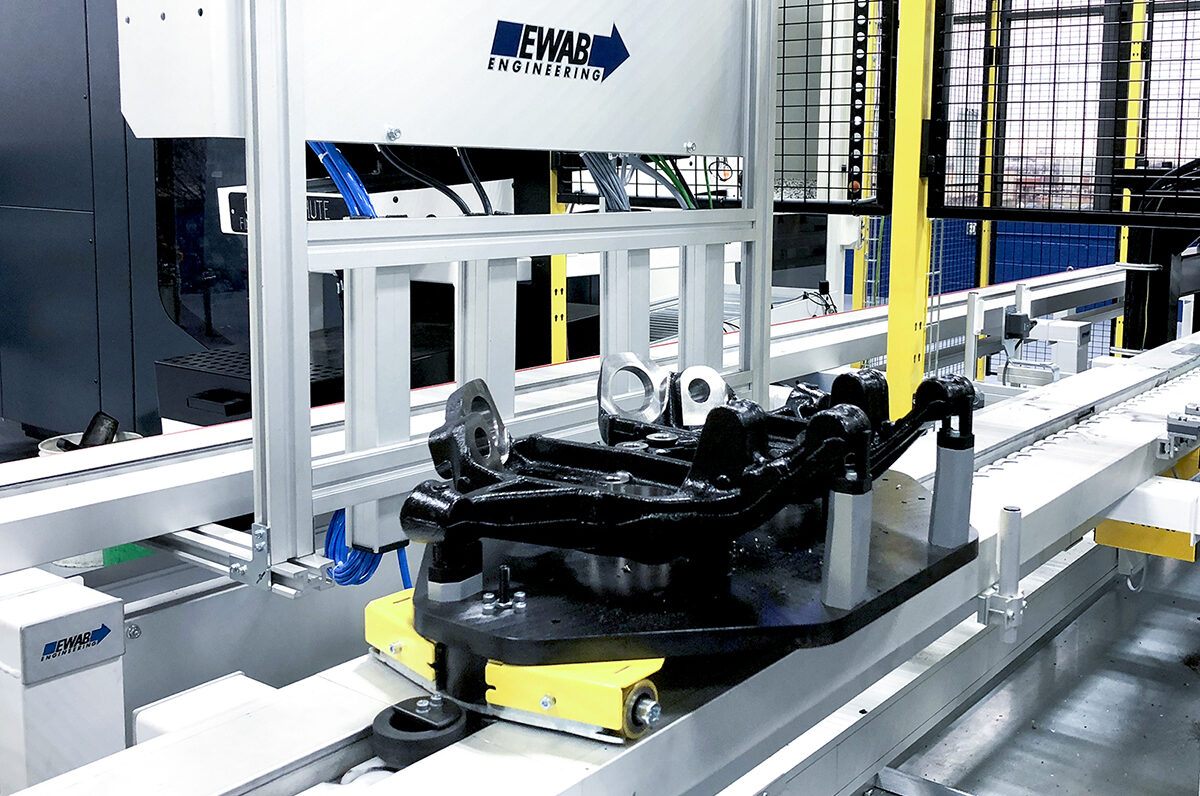

The pallet conveyor system is using pallets to transport workpieces between operations in manufacturing and assembly operations. All from single cell setups to multi-process operations.

Tabletop Systems (TS)

Need to transport the parts directly on the chain? TS is mostly used to transport parts in and out of a machine or a robot cells. We have solutions with steel or plastic chain.

Other Conveyor Types

In our automation projects we have solutions for all type of conveyors. Use a roller conveyor for smooth movements, belt conveyor for simple transport and chain conveyor for heavy parts.

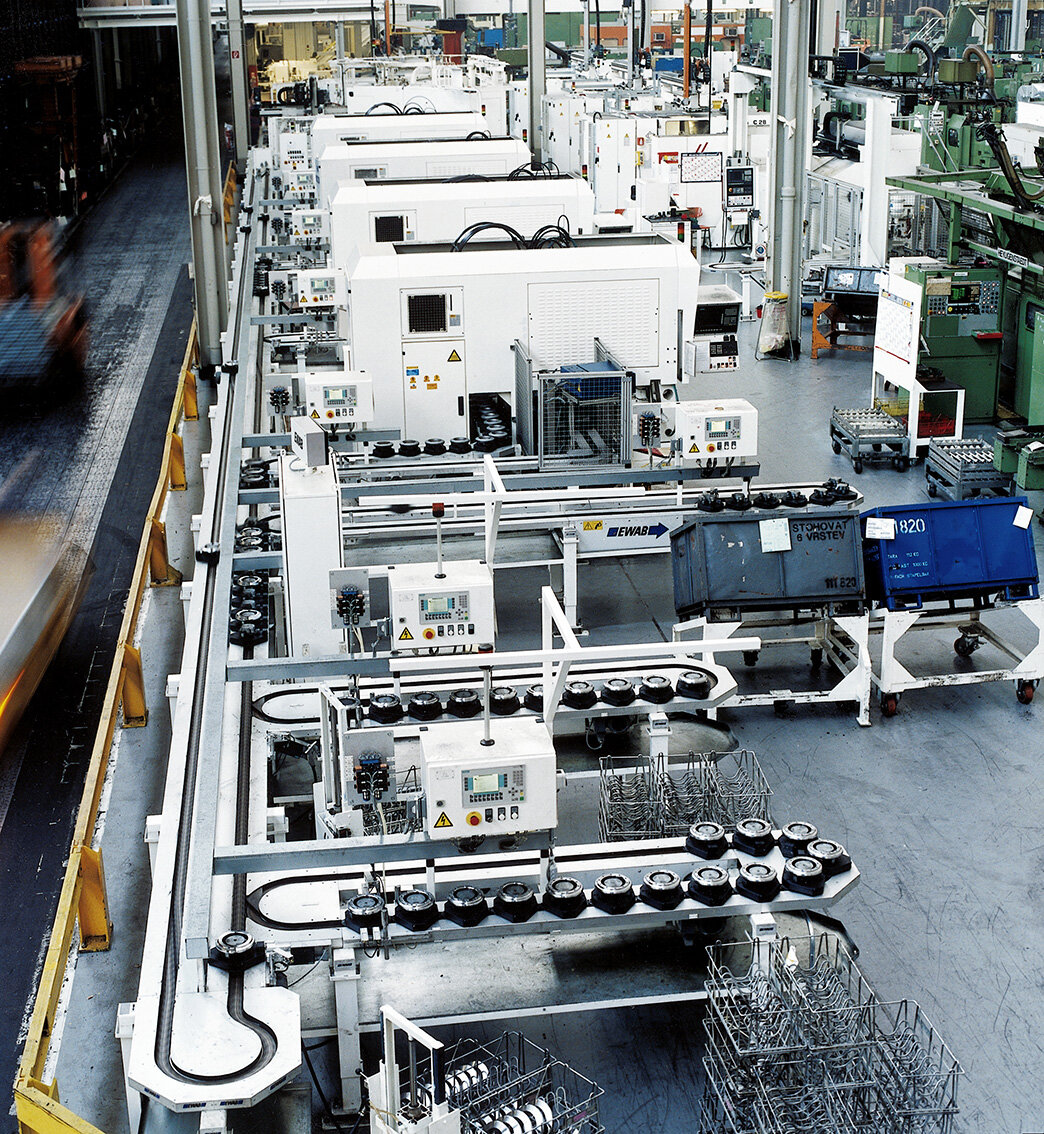

Pallet conveyor systems

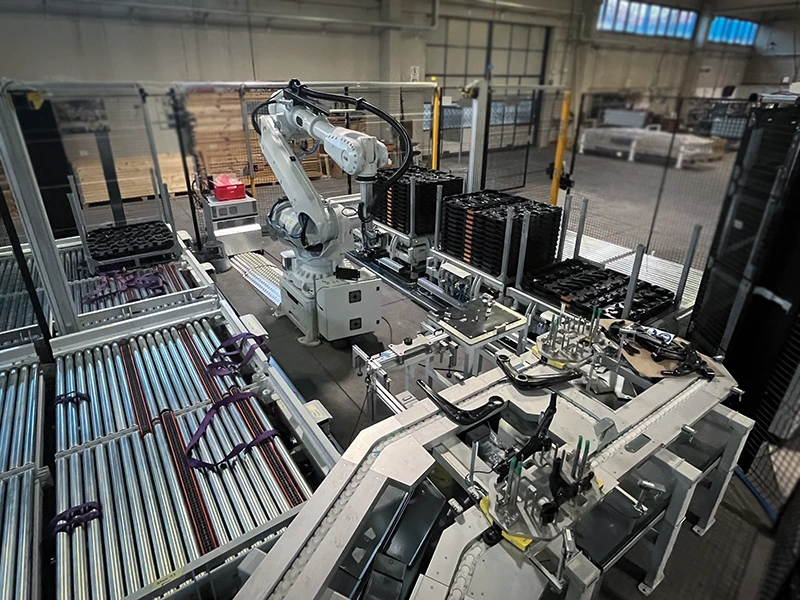

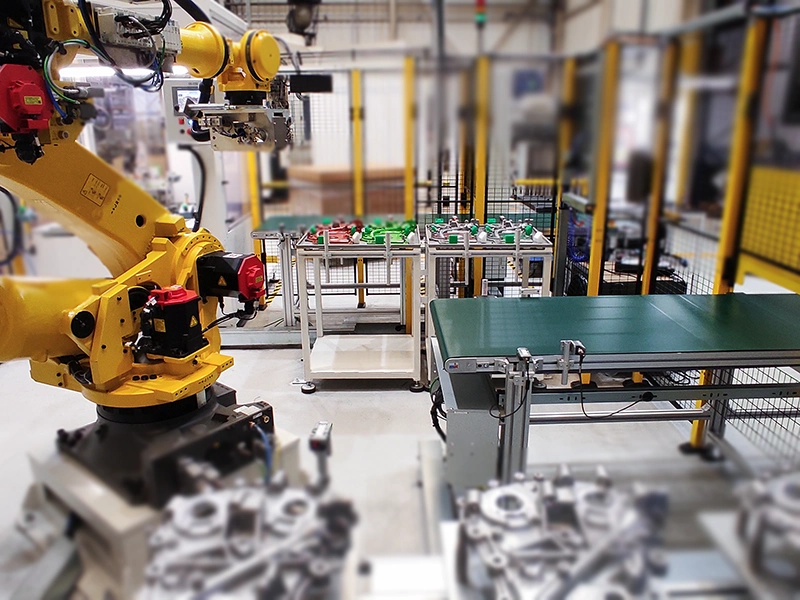

This is a modular and customized innovation that can be designed from effective single cell solutions to fully automated multi process flow systems.

The conveyor system is ideal for flexible production systems with high-volume or mixed flow. For decades, it’s been demonstrated that transporting pallets via friction on plastic chains is the most efficient method for connecting machines in manufacturing.

These systems gives you high performance, less WIP and a higher margin per workpiece.

“Trusted by manufacturers worldwide”

Flexible flow lines

Flexible flow and pallet conveyor systems.

- Multi process flow system

- Material is distributed on the pallet conveyor systems between all operations automatically

- From anywhere to anywhere

- Several products in mixed flows possible

- System output is optimized (pull)

- Dynamic buffers

- Layout based on highways and satellites

- Shortest possible throughput time

- Modular and reconfigurable solution.

- With RFID seamless parts traceability

- PS800 and CS200

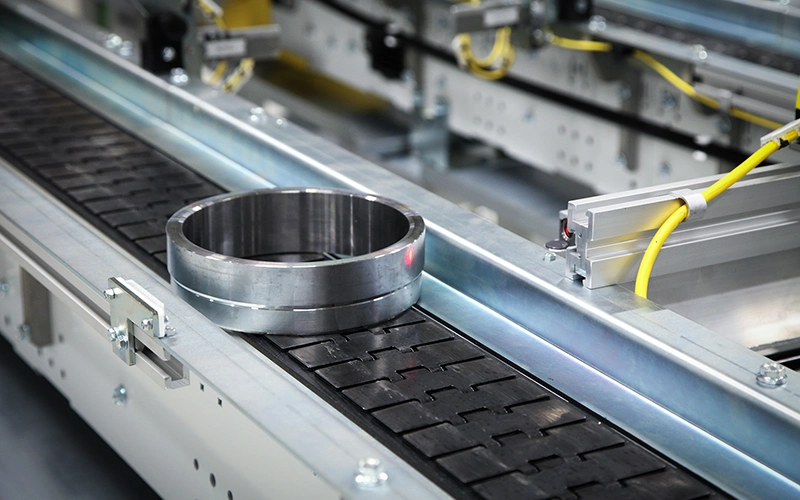

Continuous flow lines

Pallet conveyor for serial & parallel operations.

Automated conveyor system used in both assembly and manufacturing.

- Material is distributed on the conveyor system between all operations automatically

- Material can be guided instead of autonomous

- Operations in sequence

- The capacity is often balanced

- Buffers necessary between operations

- Modular and reconfigurable solution.

- With RFID seamless parts traceability

- PS800, CS200, CS900

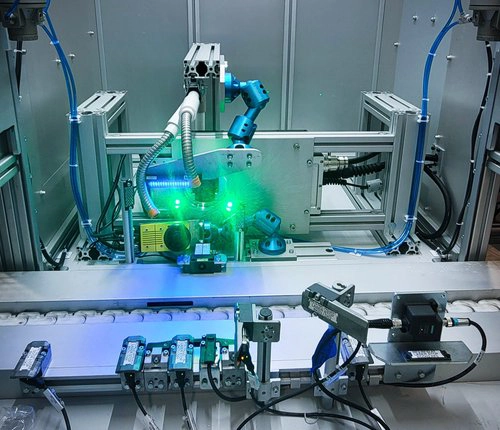

Additional Equipment

Pallet conveyor systems features

- RFID traceability – Complete traceability of all manufactured components

- Lift station – Get the right position for loading the machine

- Shot-pin – Extra fixation for the pallet

- DMC reader – Data matric code reader can read multiple barcodes on image

- Swing gate – Get through the conveyor for cleaning and maintenance services

- Track lift – Possibilities to lift a track to another level

- Pallet turner – Turn a pallet on the conveyor

- Part turner – Turn a workpiece before and after operation

- Poka-Yoke – A mechanism in a process to avoid mistakes and errors

- Code reader – A ring code reader can scan your workpieces

- Laser Marking – For high-quality, permanent labeling of parts and tracking.

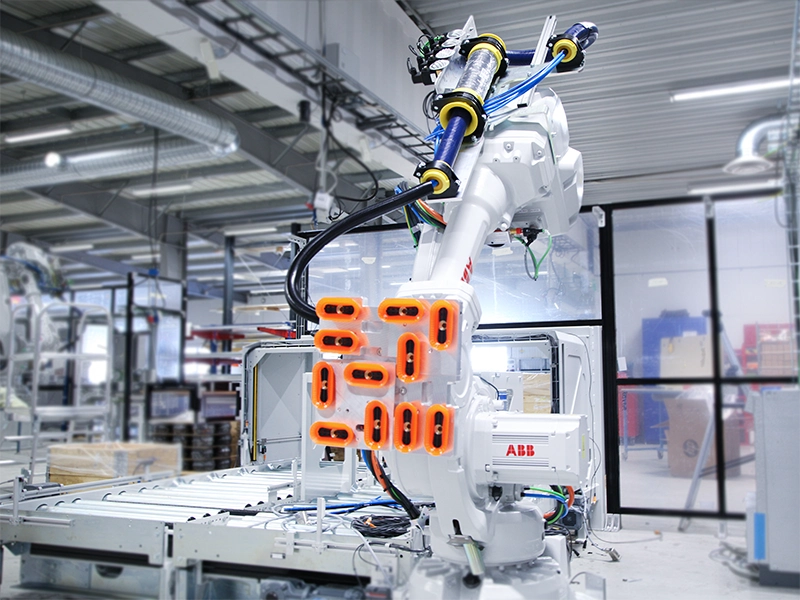

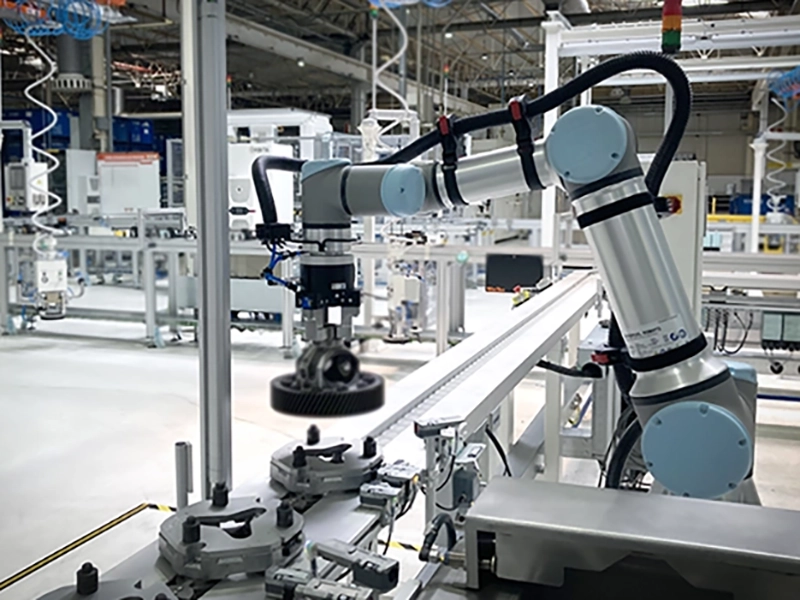

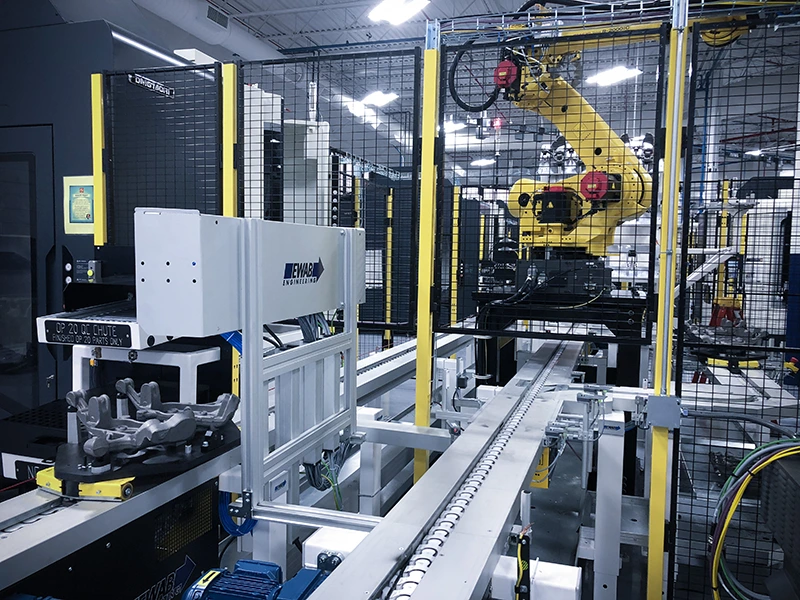

- Loading devices – Robots, gantries, portals, pick and place systems

- Digital services – Connect your EWAB systems for data insights

- Stations to your material flow line – Laser marking, SPC, washing etc

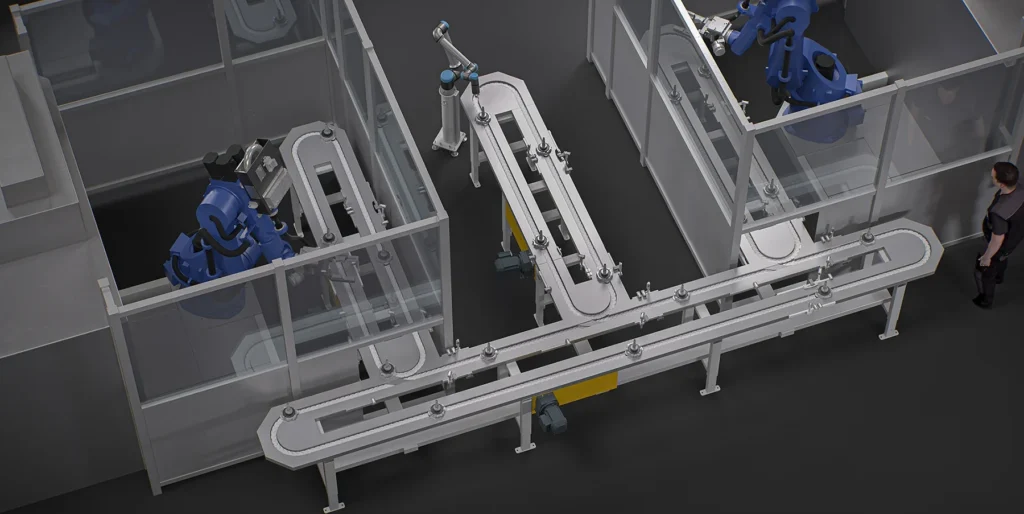

Tabletop system (TS)

TS-conveyor is made for transport parts directly on the chain

- Mostly used when the objective is to transport parts in and out of machines and robot cells.

- TS can also be built as a larger system to connect operations

- Normal speed 6-8 m/min

- Steel or plastic chain

- Wide range 144mm or 190 mm

- Weights up to 20kg / 45 lbs

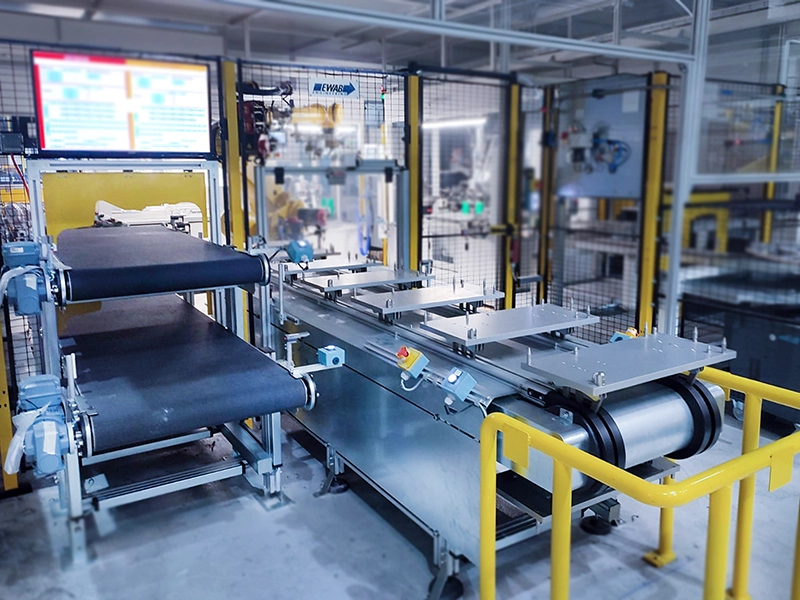

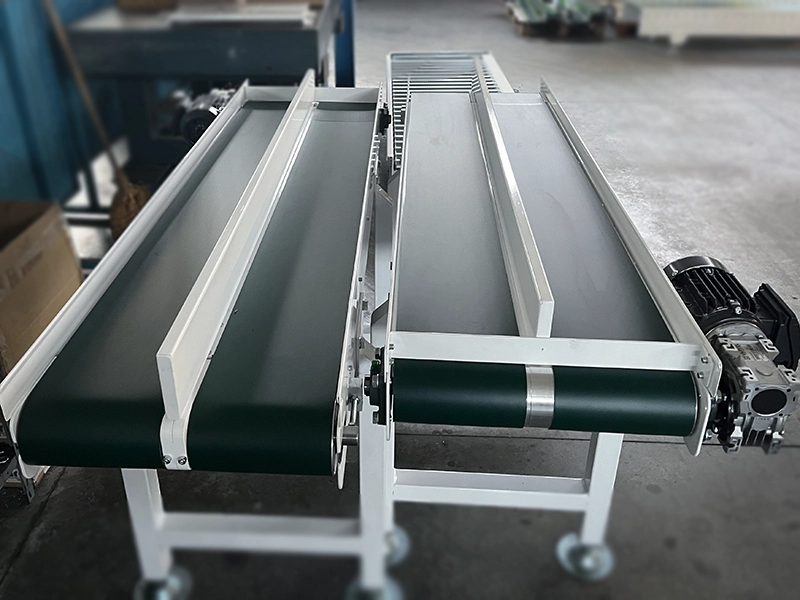

Other Conveyor types

In our automation projects we offer solutions for all type of conveyors.

- Belt conveyor to simple transport items over a flat surface.

- Roller conveyor for smooth movement of items, often gravity-fed.

- Chain conveyor for heavy-duty transport, often EU-pallets and heavy parts.

- Proven experience in handling the loading and unloading of robotic cells.

- And of course many other variants to your specific project.

Benefits of the pallet conveyor system

A pallet conveyor system streamlines material handling by automating the movement of parts and assemblies across production stages. It enhances workflow efficiency, reduces manual labor, and minimizes handling errors. With precise routing and positioning, it supports just-in-time manufacturing and improves overall productivity. Modular and scalable, these pallet conveyor systems adapt easily to changing production needs, making them ideal for both small and large-scale operations. By integrating seamlessly with robotic cells and other automation technologies, pallet conveyors help manufacturers achieve higher throughput, better quality control, and a safer working environment.

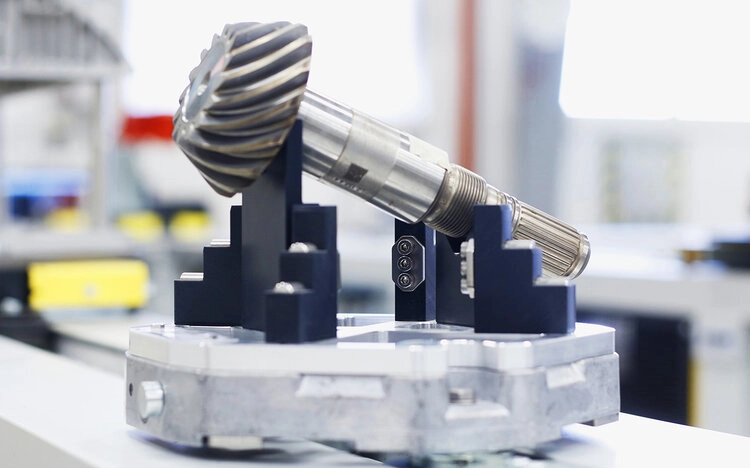

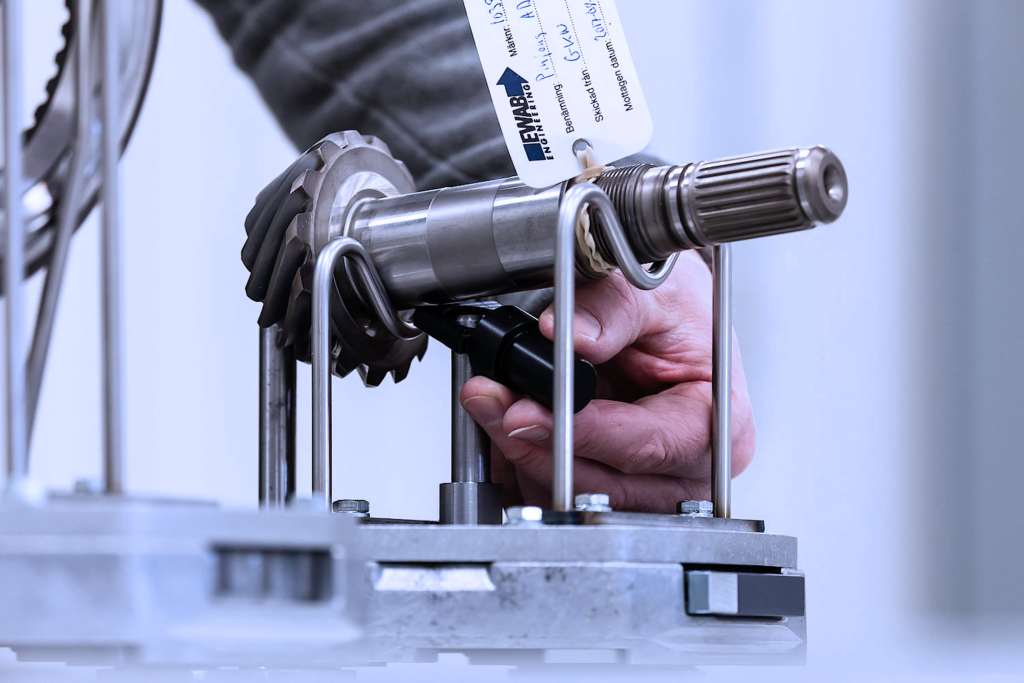

The size, shape and weight of the Workpiece is the main characteristics taken into consideration when designing your EWAB system solution.

Add robot loading of machines to your conveyor system.

– Smart industrial automation

Data insights that truly improve your manufacturing. Get reports of the lines. Takt time, cycle time, local efficiency, idle time of machines and much more.

Learn how conveyor automation can be a game changer.